Thermal Management

Our thermal management products are designed to provide an effective path for heat dissipation with minimal complication to the manufacturing process.

These materials allow to minimize the thermal contact resistance between an electronic component and the heat-sink.

Thermal Interface Materials (T.I.M.) reduce microscopic air voids, caused by surface roughness, surface concavity, and other mechanical imperfection. These imperfections or “micro pores” impede the heat flow and increase the contact thermal resistance with the result of a short lifetime of the electronic component. T.I.M. increase the heat flow and the thermal conductivity of the heat transfer system.

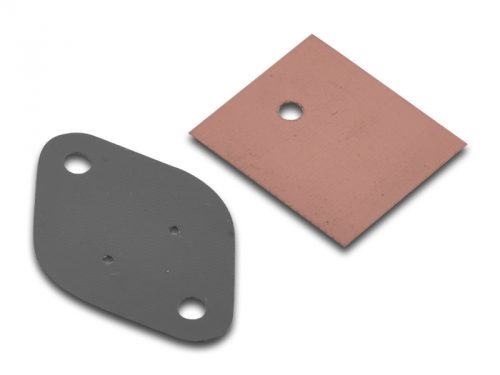

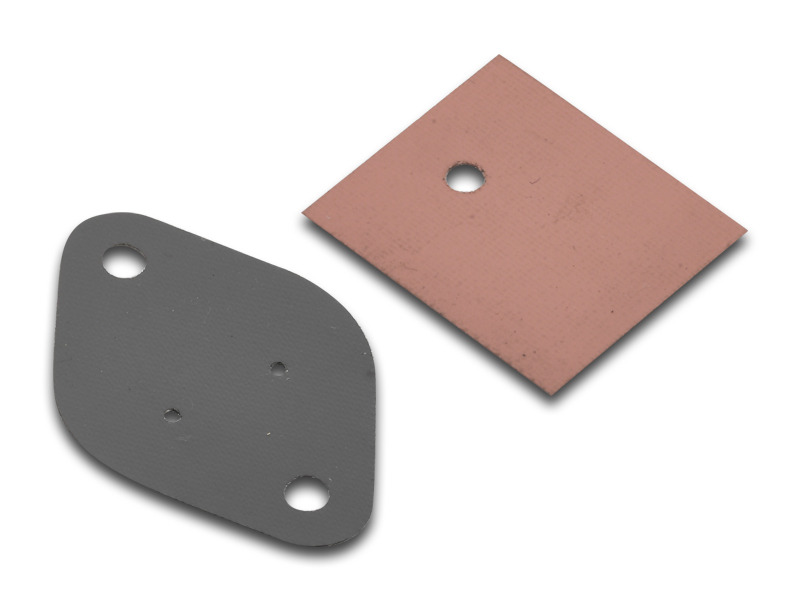

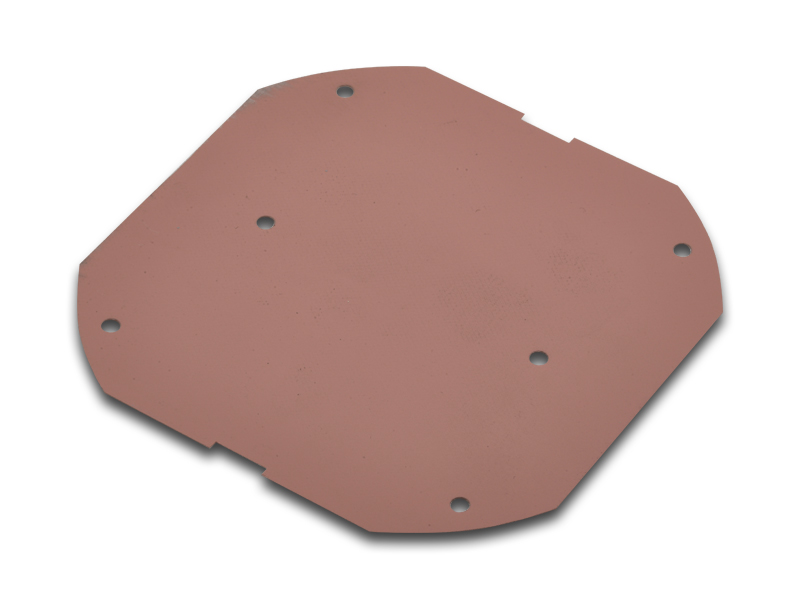

Futura provide a wide range og T.I.M for each specific application:

- Electrically Insultating Thermal interface materials

- Electrically and Thermally conductive materials

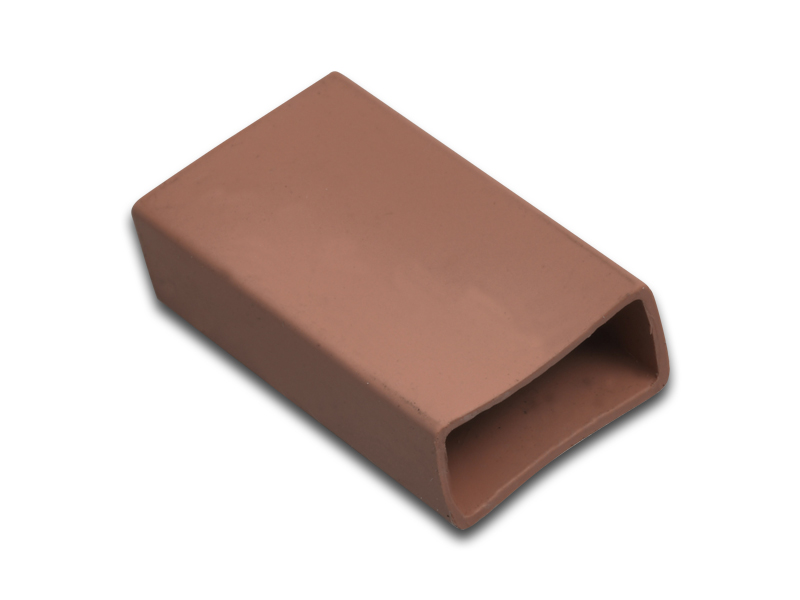

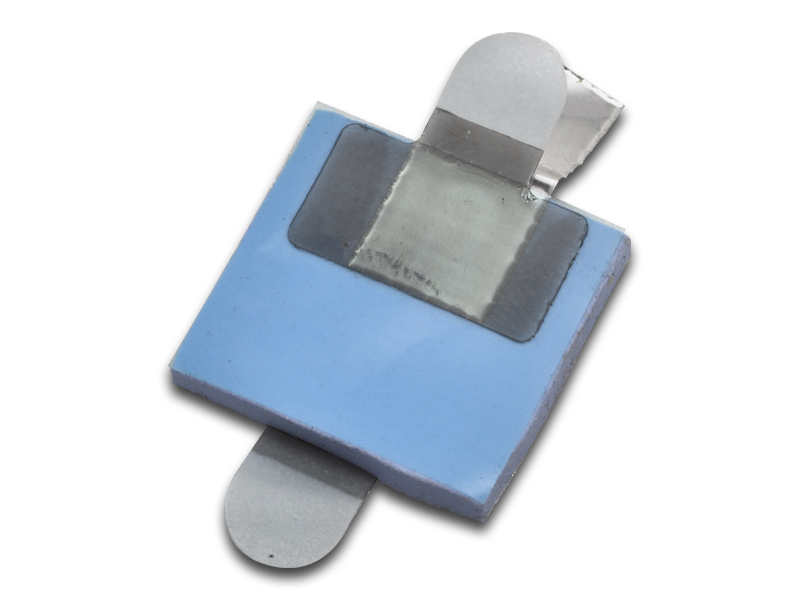

- Thermal clips

Electrically Insulating T.I.M. are used where it is necessary to improve the thermal conductivity of the system, providing in the meantime a good electrical insulation. Different materials with a complete range of thermal conductivity (W/mK) and hardness (Shore 00) can be provided.

Electrically conductive T.I.M. are realized on an electrically conductive support, as aluminum or graphite. In this category, we focus the attention on the pure graphite and phase change materials (typically, aluminium or polyamide coated with material changing its phase over a fixed temperature).

Our Engineering department can support the customer in each project stage:

- Selection of the best material for each application

- Fast prototype on customer drawing

- Mass production

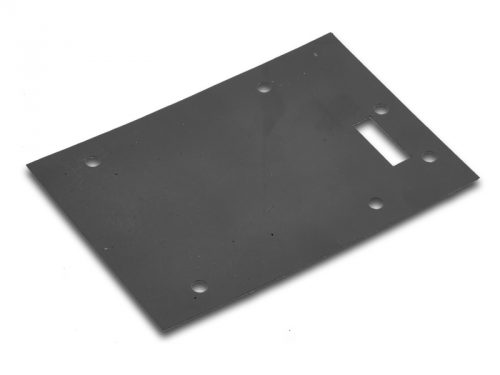

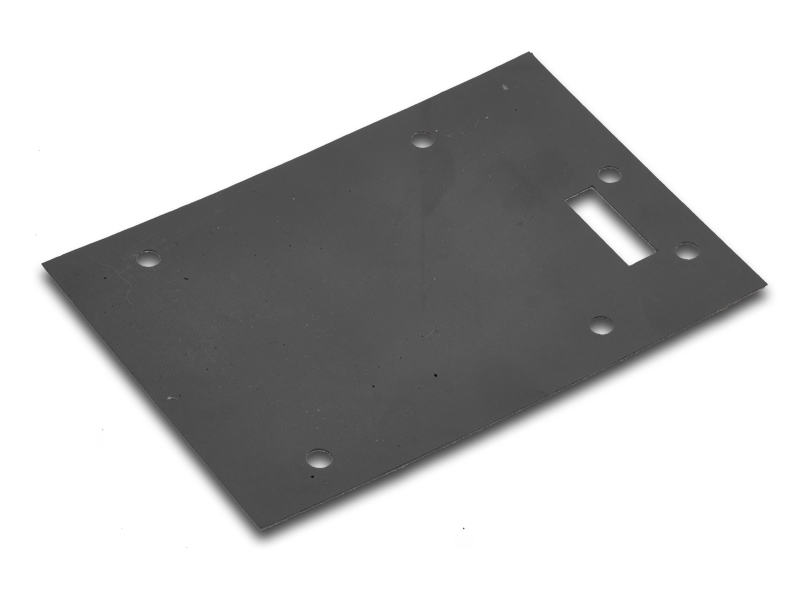

These materials can be cut according to customer drawing by our wide range of cutting equipments.

Sampling available in 48 hours.

Download

Request informations

FUTURA SRL

Via Tagliamento 16/18 - 20098 San Giuliano Milanese (MI): +39 02 9881193

Fax: +39 02 98282216

info@futura-italia.it

VAT IT IT 08844930159

R.E.A. n° 1250938 | Reg. Imp. Milano 08844930159

Capitale Sociale € 200.000,00