Optical filters

Futura provides customer specific optical filter solutions.

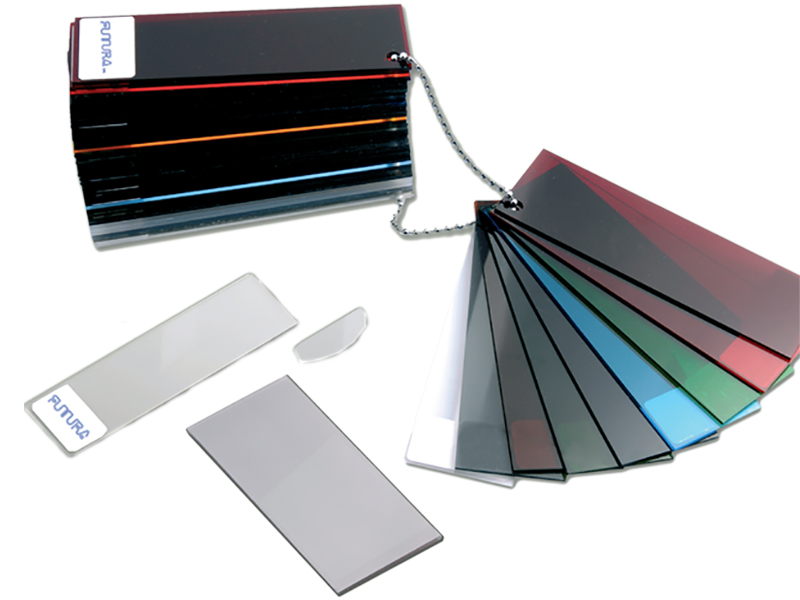

We can manufacture a wide range of filters:

Contrast Filters: used to increase the readability of visible light from displays and monitors. This is done by adapting the contrast filter’s transmittance to the wavelength of the light emitted from the display, so that the secondary light is blocked. The narrower the transmittance curve in the desired wavelenght region, the greater the contrast. The filtering process also means that the amount of reflected light from the surface of the display is so limited that the mechanical components and electronics which lie behind the filter are partially or fully hidden.

It is possible to create a high degree of contrast by either a filter with narrow transmittance curve or a dark tinted filter. The latter will make information from the display stand out clearly against a dark background. This may increase readability and provides an elegant design function.

LCD filters: optical filters used for LCD application with a high transmissivity performances. Our LCD filters are produced in transparent acrylic but with an integrated light guiding material. In this way, it is possible to obtain the same high transmittance as transparent acrylic with high contrast and thus greater readability. Our LCD filters absorbs the sun’s harmful UV rays below 400 nm.

Infrared filters: Infrared filters are used in sensors, security systems, scanners, IR camera, and in all the application where it is necessary to exclude visible light.

Shielding windows: to control electromagnetic interference. Shielding window is a balance between the shielding effect and the light transmission. It is important to reach the required shielding performance with the maximum readability.

Diffusion Filters: used mainly for back-lighted LCD modules, such as passengers information systems at airport and train stations.

Polycarbonate Filters: highly resistant to shock and impacts.

We offer high quality filters as we use the best cast acrylic. Cast acrylic ensures a very regular surface of the optical filter and a minimize the optical imperfections.

We supply different surface treatment solutions:

- Hard-coating: high performance optical grade hard coated cast acrylic. The surface hardness is very high, until 6-8 H. So we can meet all customer’s demands for scratch resistance.

- Standard surface treatment: to be used when significant reduction of disturbing reflections with no loss or distorsion of light is a priority. It is especially developed to produce a mat, exclusive looking surface for elimination of reflections and perfect optical performance

- AR-coating: Anti reflective coatings are made by applying series of very thin layers of metal and mineral oxides on top of each other in a vacuum deposition process. It is important to control and properly design these layers so that all the light will be totally transmitted and not reflected when arriving on the acrylic surface. This allows to improve the clarity and light transmissivity. This coating can be combined with Anti Finger Print coating. This coating is the best choice for application where optical perfection is a goal.

Request informations

FUTURA SRL

Via Tagliamento 16/18 - 20098 San Giuliano Milanese (MI): +39 02 9881193

Fax: +39 02 98282216

info@futura-italia.it

VAT IT IT 08844930159

R.E.A. n° 1250938 | Reg. Imp. Milano 08844930159

Capitale Sociale € 200.000,00